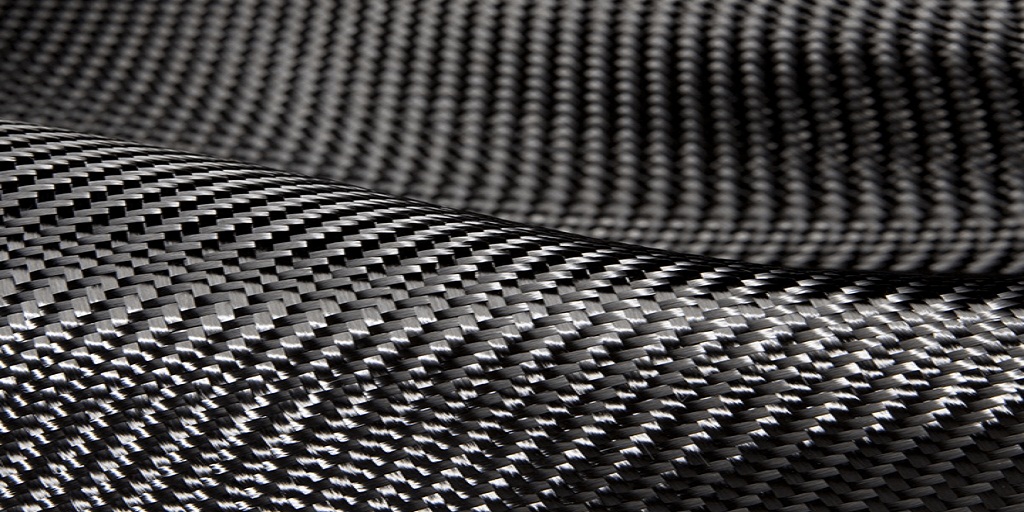

Need to custom cut carbon fiber sheets for your project? There are many different ways you can cut graphite fibers and several tools you can use to do it. The tools you’ll need are probably already in your garage, but we’ll get to that.

First, let’s talk about how you can minimize health and safety hazards when cutting carbon fibers. Read on.

Be on the Safe Side

Carbon fiber itself and its dust aren’t toxic. The danger is in when you inhale the dust. This polymer is associated with lung problems in people.

Carbon fiber is also hazardous to electronics because it can conduct electricity. A small amount will not be enough to short circuit your appliances but they can if they pile up.

So make sure you:

● Work outdoors

● Wear a mask

● Use eye protection

● Wear protective clothing

● Wear gloves, and

● Use a cutting tool with dust extractors, if you can

Cutting Tools You Can Use

Carbon fiber sheets that are thin (up to .20mm) can be cut with scissors or knives. For thicker plates, abrasive cutting wheels and Dremel cutting tools can increase cutting efficiency.

Here are other cutting tools you can use:

● Drill (carbide-tipped if you have one)

● Waterjet

● Jigsaw

● Rod saw

● Hacksaw

Tips for Cutting Carbon Fiber Plates

1. Use different abrasive sizes of sandpaper when sanding

To smooth the edges and avoid getting splinters, be sure to use sanding paper for the edges. To minimize dust, you may opt to use wet sandpaper.

It’s best to start with coarse sandpaper for the rough edges, then switch to 200-grit to 220-grit sandpaper to smoothen them and make a polished finish. Be careful when you’re sanding, it’s very easy to slip and scratch the surface of your plate.

2. Use metal-working file for the corners

Use a flat or round metalworking file for the corners. Finish it off with the sandpaper and make sure to go from coarse to fine sandpaper grit.

3. Cut wider than your dimensions

Mark your cut a bit wider. The excess is for the part you will sand and polish for a fine finish.

4. Measure twice, cut once

You can use a metallic silver pen for marking. (Any remaining ink can be removed with acetone and a soft cloth.) Alternatively, you can apply masking tape to the area and use a regular pen or a pencil to write on top of the masking tape.

Measure twice or more for accuracy.

5. Get a clean, hard finish with epoxy resin

You can also seal the edges with epoxy coating resins. If your project will be exposed to the elements or other harsh environments like the marine, you can seal the edges with this coating.

Cutting carbon fiber plates involves health and safety hazards so safety practices must be observed. In cutting, you may use regular steel cutting tools but for faster cuts, Dremel tools and tools that have carbide cutting wheels are recommended.

If you need more carbon fiber sheets or you have yet to buy some, check out Protech Composites. They offer globally competitive, high-quality carbon fibers. Plus you can count on solid customer support. Contact them today.