Compressed air is a marvelously utilitarian energy source that can be used to power everything from pneumatic tools to machinery and automation equipment and even transportation. It can be used in areas where electrical power is infeasible or cost-prohibitive, far away from established electrical grids.

But compressed air power, like all forms of energy, is not without its quirks. Take, for example, condensates, which are present in some form or other in compressed air systems and which can cause corrosion and other damage.

Before use, compressed air dryers remove the bulk of condensates from a system, but condensates can still form and accumulate within the compressed air system itself.

Removing them requires specialized drain valves, and zero-loss drain valves are among the most specialized of all. Here’s what you need to know.

What Is a Zero Loss Drain Valve?

Zero-loss drain valves, like manual drain valves and solenoid-operated drains, remove condensates from compressed air systems. The difference is that zero-loss valves only open when condensates are present and, most importantly, do not allow any of the compressed air to escape from the system.

Most zero-loss valves are calibrated to open once a threshold is reached, and close once a minimum level of condensate is achieved. They close before any of the compressed air (or gas) in the system can escape.

Protecting Your Equipment

Like all drain valves, zero-loss drain valves help prevent condensates from ruining your processes, damaging your equipment, or adversely affecting the quality of your finished products.

Condensates in compressed air systems can cause corrosion to piping and can also damage pneumatic controls. Condensates can also cause water damage to circuits and filters. Worse, condensates present in and around a compressed air system can also lead to the corrosion of production equipment.

Where condensates are present in compressed air systems and a rapid change of pressure occurs (which is common) hydraulic shock (“water hammer”) can damage pipes and fittings, and even cause potentially catastrophic failure of equipment and components.

Condensates themselves can also complicate or compromise the quality of finished products. For instance, in industries such as pharmaceuticals and cosmetics, in which compressed air may be used in packaging, water intrusion can cause significant damage to finished goods.

Moreover, when damage occurs to a compressed air system, repairing it and bringing the system back online can be time-consuming and expensive. Since time can be considered money, it’s doubly expensive.

Condensate drain valves of all sorts can help prevent damage to equipment and the costly downtime that ensues, but zero-loss drain valves have an extra edge – no loss of pressure.

Saving Money

Compressed air isn’t cheap. It needs to be compressed (which takes energy) and dehydrated (which lengthens the process) before it can be used. Letting out compressed air from a system at the point of a drain valve is literally bleeding money.

This is similar to how corona discharge along high-voltage lines causes voltage drop and costs utilities companies money. The difference is, there is often nothing that can be done about that, and in compressed air systems, all you need to do is not let the air out. Preventing compressed air loss is tantamount to saving energy.

Zero-loss drain valves typically have a higher upfront cost than manual drain valves, but they typically pay for themselves within a year or so due to the increased efficiency they lend to the system.

In other words: a zero-loss condensate drain can save you money on the operating costs associated with maintaining a compressed air system.

High-Quality, Reputable Zero-Loss Drain Valves

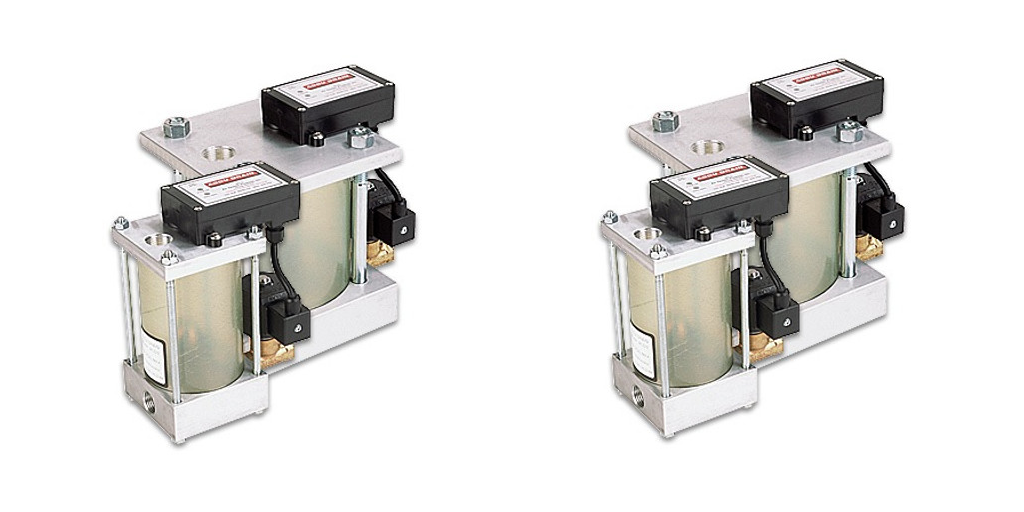

To learn more about zero-loss drain valves or to see what models are commercially available, visit Air and Vacuum Process online at AirVacuumProcess.com. They carry a wide range of zero-loss valves, including Robo-Drains and corrosion-resistant stainless steel valves.